Toyo Supply Co., Ltd.

We are importers and exporters of metal sheet roofing machines, PU foam rolling machines, ISO wall rolling machines, and EPS rolling machines. The group was established in 1992 and has been around for over 30 years.

- home

- products

- EPS extruder

EPS extruder

| section | details |

|---|---|

| EPS machine |

- Speed: 2-4 m/min depend on Glue style - Core materail : EPS - Warranty : 12 months - Required Power Supply: 3 phase/50hz |

| 1. EPS LOADER : 1PC |

- Length of EPS Loaded machine: 6m - Heating of pvc conveyor belt lead in - Driving Motor Power: 0.75 Kw x 2 |

| 2.PRESSING GLUE SIDE MACHINE 8M : 1PC |

- Steel frame : 160 * 80 * 6 - Roller shaft diameter : 155mm - Thickness of composite rubber layer: 7mm - Number of rollers: 22 pairs - The shafts are connected to a conical gear system to create a uniform motion system |

| 3.GLUE APPYLING MACHINE |

- Number of pump: 4 sets 2CC Tasheeng - Power: 0.75 Kw per pump - Flow volume of glue: 0 – 0.4 kg per pump - Type of flow volume control: Frequency inverter - Scale of glue: (as request of suppiler ) - Glue spreader pipe: standless steel pipe with hole ( 6 pipes according to machine and 6 pipes prevention ) |

| 4.GLUE SPREADING DEVICE: 2 SET |

- Spreading speed : 80 times/ min - Capacity : 0.75 kw x 2 sets - Noted : top surface of sheet is spread with glue and then tool spreads it evenly |

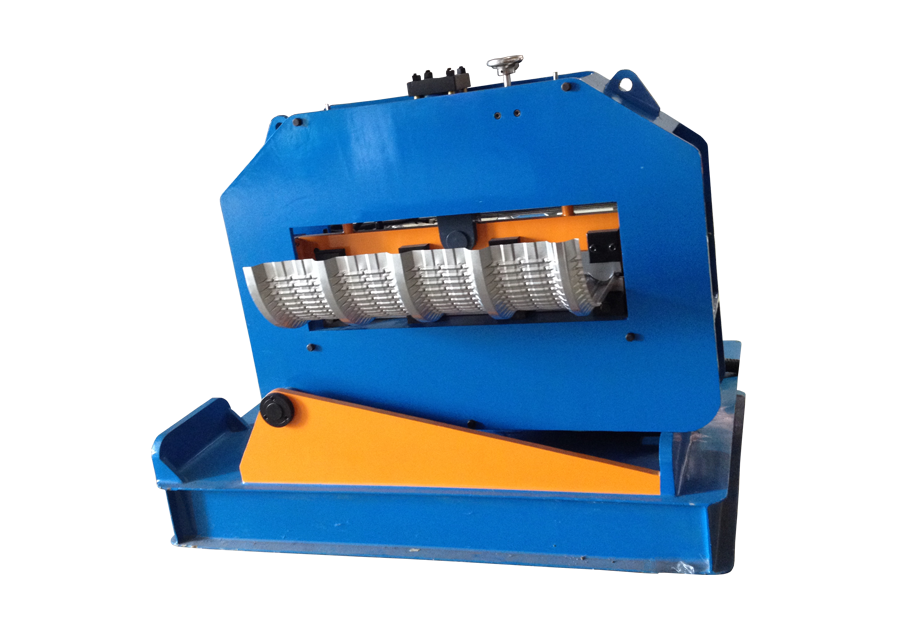

| 5.RIB ROLLING SET : 02 SET |

- Used to roll rib onto flat sheet surface - Can adjust rolling rib or not rolling rib |

| 6.FLAT SHEET CUTTING BLADE SET : 02 SET |

- The cutting blade is made of SKD steel through heat treatment - Cutting motor : 1 HP ( SGP) |

| 7.DEVICE PROTECTIVE FILM PANEL: 02 SET |

- Apply anti- scratch film to the Panal surface - With tool roll holder and gluing speed adjustment |

| 8.FOLD EDGE MAKE BODERING PANEL SET |

- Create positive and negative mounts for Panel - Include 2 sets of folding up and down rollers made from SKD steel through heat treatment - Move in /out when change size by handwheel |

| 9.FOAM MILLING PARTS |

- Milling foam to create mounts for Panel - Electric Engine 0.75 kw( SGP ) - Foam milling blade is made of SKD steel through heat treatment |

| section | details |

|---|---|

|

- Number of rolling shaft: 5 guaranty apply material for 4 thickness profile 50, 75, 100, 125 and 150mm - Control Roller shaft: gear motor 1HP (0.75kw) - Control motor : inverter - Change size 50mm -> 150mm : turn the hand to increase the size based on the ruler line. - Raw material Thickness : 0.3mm – 0.5mm |

|

| CUTTING HEAD AUTOMATIC : 01 PC |

O Dimension : LxWxH 4300 x3300x 2300mm O Weight: 3,5 tons O Materail : Steel ( plate , box ) O Required Power: 5HP ( 3.7kw) x 2 PCS, 1HP (0.75kw) x 2PCS O Thickness of Panel: 50-75-100-125-150mm O Movement of Cutter: 1800mm (cylinder distance) O Speed 3-5m/min with shortest sheet 2-2.5m. O Cut by 2 disc cutter , diameter 355mm x 2 pcs, from size 50-75-100mm In case of size cutting from 100-125-150mm : must raise the upper cutting assembly and manually adjust the lower cutting assembly When cutting rib sheet , must put a rubber lining on it to prevent the cutting from denting the rib O The cutting blade generates bavia O Air Tank capacity : 77 liters O Vacumm cleaner: 3 HP O Control by : PLC Siemens O Magnectic starter :Schneider/Himel/Sigma O Save order and extract file to host machine O Emergency stop button ( STOP ) is designed both side of machine , position of cutting head and material feeder part is on the control board. |

| UNCOILER BY HAND: 4 PCS | Unbent 460 – 515 |

| Electrical control system | |

| For EPS |

- Use a vertical electric control cabinet - Central control device Mitsubishi PLC - Control of lifting and lower the system - raising and lowering the foam pulling shaft manually ( Use push button and raise - lowering according to ruler) - Cut the tail automatically under control of cutting head automatic - Switchgear MCCB/MPCB/MCB: Schneider / Himel/ Chint - Intermediate device ( Contactor/ Relay ) : Schneider/ Idec |

| FOR Cutting Head Automatic |

- Use a vertical electric control cabinet - Central control device PLC Siemens - Touch Screen Delta 7" - Manually control the raising and lowering of upper blade according foam thickness ( Use push button and raise - lowering according to ruler) - Enter up to 80 orders at the same time , cut of automatically - Save day's production orders to screen. View produced order data directly on the screen or export to USB - Switchgear MCCB/MPCB/MCB: Schneider / Himel/ Chint - Intermediate device ( Contactor/ Relay ) : Schneider/ Idec |

products

- PU Foam Extruder

- 760 Corrugated steel roofing machine

- Spanish corrugated steel roofing machine

- Hydraulic uncoiler 1.2 m.

- Steel roof curve crimping machine

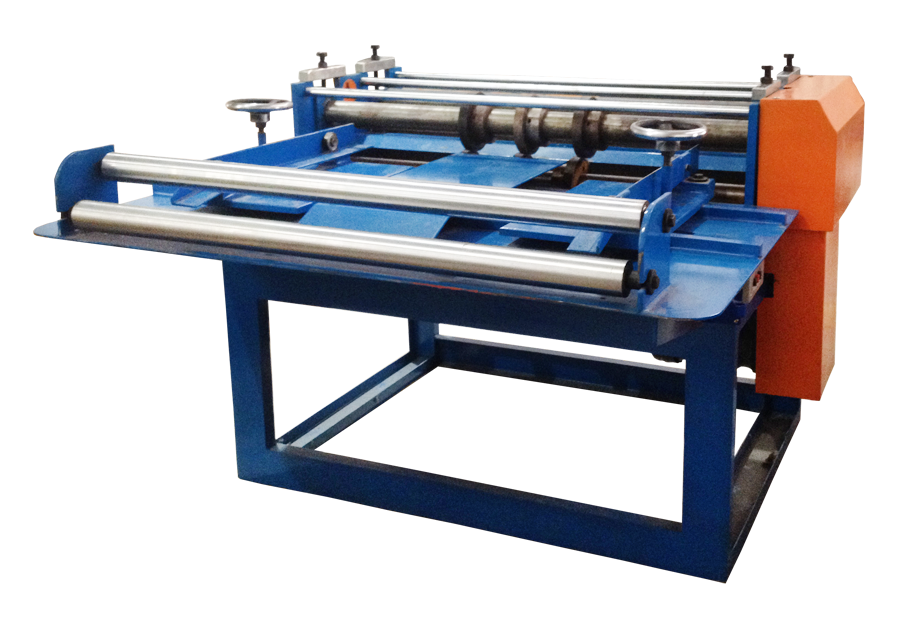

- Sheet cutting machine

- Hand-operated folding machine 4.50 m.

- Hydraulic folding machine 4.50 m.

- C and Z shaped steel rolling machines

- Foil ironing machine

- Corrugated iron roofing machine 850

- Shuttering machine

- Side covering ironing machine

- Gable covering machine

Contact Us

-

Toyo Supply Co., Ltd.

- Tel: 042-326647-48

Phone 081-6611286,081-871-6303 -

Toyo Supply Co., Ltd. Bankok Office 12/229 Moo. 7

Lat Sawai LamLukka Pathumthani, 12150 THAILAND - Tel: 094-2742225,098-5853540

- Email: salestoyo02@gmail.com

-

Business hours Mon - Fri 08:00 - 17:00

Sun: Close

Toyo Supply Co., Ltd. 369/1 Rop Muang Road (Kao Noi)

Markhaeng UdonThani 41000 THAILAND